© Whitecell Eisenhuth GmbH und Co. KG

© Whitecell Eisenhuth GmbH und Co. KG

Optimize components

Making bipolar plates for water electrolysers cheaper and more robust

Thorsten Hickmann Mission Hydrogen 2030

The process for producing hydrogen must become cheaper and more reliable. In the TiCoB project, researchers have therefore developed a novel bipolar plate to optimize this electrolyzer component in this regard. Project manager Thorsten Hickmann from Whitecell Eisenhuth explains exactly how the team achieved this.

© Whitecell Eisenhuth GmbH und Co. KG

© Whitecell Eisenhuth GmbH und Co. KG

What was the main objective of the TiCoB project?

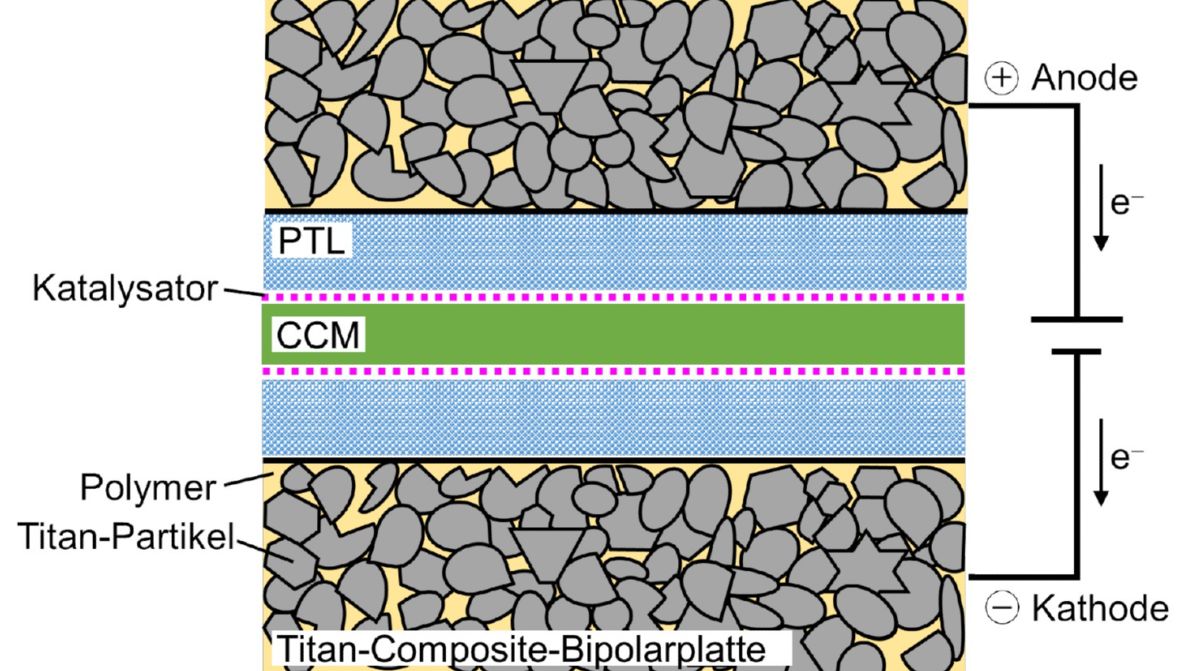

Thorsten Hickmann: We wanted to develop more cost-effective and robust bipolar plates for water electrolysers. These plates are an essential component in hydrogen production. They conduct electricity and ensure the distribution of hydrogen and oxygen via the proton exchange membrane, or PEM for short, in the cells. The plates are therefore an important but also expensive element of electrolysers.

Why are bipolar plates so expensive?

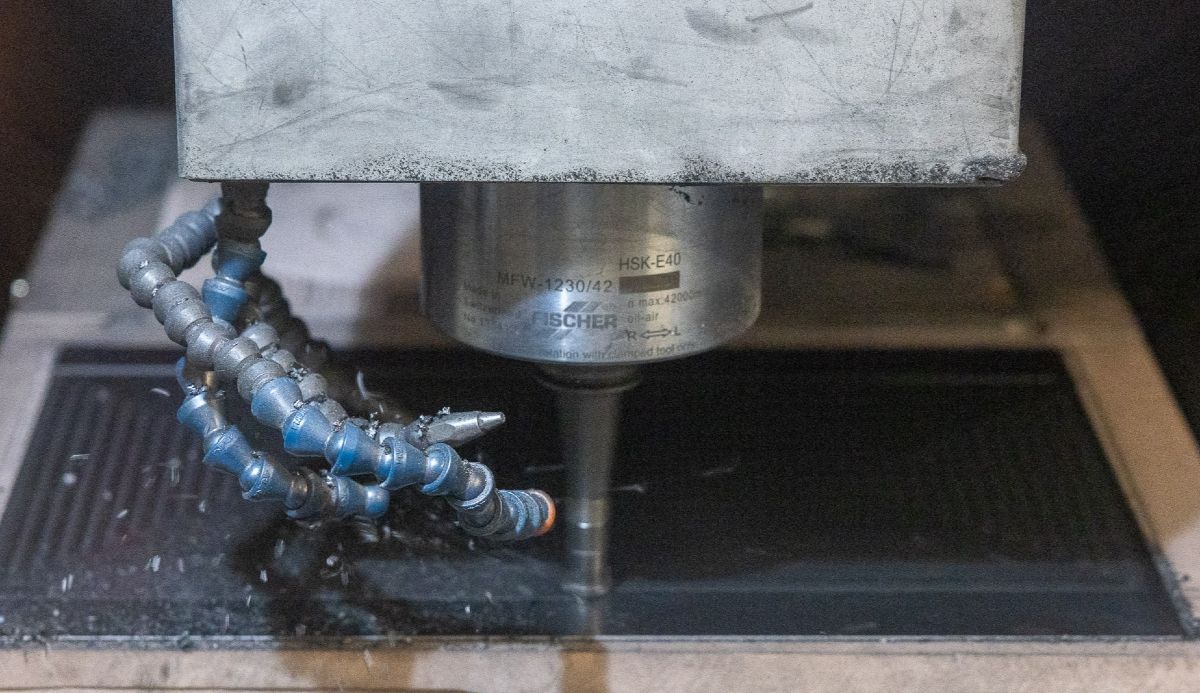

The high costs are primarily due to the use of titanium. This is expensive and requires complex processing. Bipolar plates must also meet high requirements in terms of electrical conductivity, corrosion resistance, and mechanical stability. This makes their manufacture complex and cost-intensive.

How did you approach the cost issue with bipolar plates?

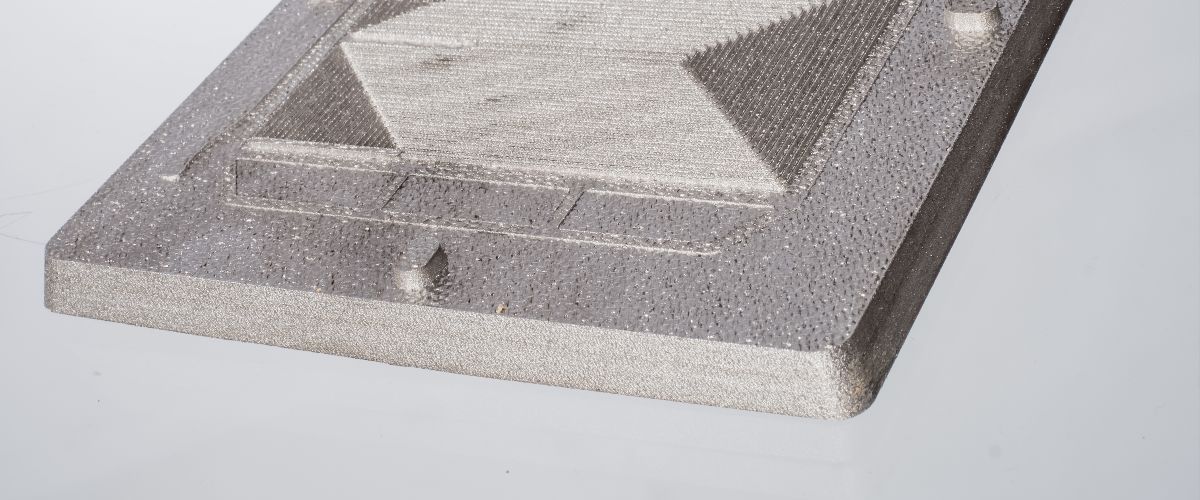

At TiCoB, we developed a new composite material. This material is suitable for use as a structured bipolar plate with a flow field. The flow field of a hydrogen bipolar plate is a network of channels that controls the flow of gas and liquid. It ensures that hydrogen and oxygen are distributed evenly. We also optimized the flow field to ensure efficient gas and electricity distribution and to guarantee the longevity of the bipolar plates. In terms of service life, this plate is on par with pure titanium bipolar plates. Our research focus was therefore primarily on significantly increasing this service life in order to make our composite material competitive. To this end, we also focused on the degradation mechanisms of the bipolar plate and investigated its interactions with other system components.

© Whitecell Eisenhuth GmbH und Co. KG

© Whitecell Eisenhuth GmbH und Co. KG

Instead of pure titanium, you have used a new composite material. What is behind this?

It is a titanium composite. The plate is manufactured using extrusion. This process is gentle on the material and cost-effective, as it eliminates the need for time-consuming post-processing. We also used a titanium powder additive in a polymer to reduce the amount of titanium required without compromising functionality.

What exactly makes the TiCoB project innovative?

The project is characterized by several innovative approaches. An important technical breakthrough was the development of a low-temperature coating process that also works at room temperature. This allows high-quality metals such as gold or platinum to be used without damaging the polymer content of the titanium compound plates. In addition, we have developed a long-term stable and corrosion-resistant coating that is specially designed for aggressive electrochemical environments.

© Whitecell Eisenhuth GmbH und Co. KG

© Whitecell Eisenhuth GmbH und Co. KG

What is so special about the new coating technology?

The coating is not only corrosion-resistant and durable, but has also been optimally tailored to the requirements of the newly developed flow field. This ensures uniform gas and current distribution, significantly improving the efficiency and performance of the bipolar plates.

What challenges did you face in developing the new plates?

Two of the biggest challenges were the lower electrical conductivity and higher gas permeability of the composite material compared to pure titanium. We were able to solve these problems through an optimized manufacturing process and special coatings. We also focused on corrosion resistance and electrical contact stability.

Where are you in the development process today?

We are currently having customers test the titanium composite plate. Demand is high, as these plates are an economical alternative to pure titanium. Their high corrosion resistance and stability make them particularly suitable for practical use.

What are the practical benefits of this development?

The results so far show great potential for practical use, including in fuel cell technology, but especially in electrolyzer technology. Improved properties such as corrosion resistance, long-term stability, and optimized gas distribution make them ideal for use in PEM electrolyzers and fuel cells. For electrolysis companies, the use of the new plates can mean a sustainable and economical solution. Material and processing costs are reduced. At the same time, the service life of the products is extended. The technology thus contributes to cost reduction and increased efficiency in hydrogen production and fuel cell technology.

The interview was conducted by Mareike Lenzen, Public Relations Officer at Project Management Jülich.