© International Partners in Glass Research (IPGR) e.V.

© International Partners in Glass Research (IPGR) e.V.

Decarbonization of the process industry

Hydrogen meets high temperatures: climate-friendly production of steel, bricks, and glass

The research projects ZeroCO₂ glass, KLIMAZIEGPROD, Hybrid-FIRE, and H₂-DisTherPro represent a new generation of industrial processes. With the help of (green) hydrogen and electricity, researchers are working to make key processes in glass, brick, ceramic, and steel production climate-neutral.

The manufacturing processes for these products require particularly high temperatures, which have traditionally been generated primarily by fossil fuels such as natural gas or oil. A number of requirements still need to be met before the transition to green hydrogen and renewable electricity can be successful. A brief insight into the four research projects reveals the challenges involved and the specific areas of research being pursued by the scientific teams.

Emissions-free glass production: ZeroCO₂ glass develops new melting tank

Whether jam or pickle jars or the classic milk bottle – glass containers and preserves are used in large quantities in everyday life. In the ZeroCO₂ glass project, a research team is working on an emissions-free melting process using bottle production as an example.

Unlike in conventional glass production, carbonate-free raw materials are to be used in the future – until now, glass has been produced from a mixture of sand and raw materials such as calcium carbonate and sodium carbonate. The researchers are also developing a new type of melting tank that can be operated flexibly with varying proportions of electricity and hydrogen-oxygen combustion. This should make it possible to dispense with fossil fuels such as the natural gas used to date. It is important to gain more insight into the influence of the hydrogen-containing atmosphere on glass production.

This involves considering issues such as the different flame properties, the increased formation of water vapour, and changes in the exhaust gas, which influence both the glass quality and the melting tank and furnace lining. The researchers are also investigating how the new glass composition affects the shaping and the final product.

In developing the new melting tank, the scientists are also taking a closer look at the design in order to optimize the batch composition. They aim to reduce the moisture content of the raw materials at the start of the process that is usually necessary to prevent dust formation. This could also further increase energy efficiency.

The researchers' goal is to develop a demonstrator of the glass melting furnace in ZeroCO2 glass. It is expected to produce around 2.4 tons of glass per day – an important step toward CO₂-free glass production.

Climate-neutral brick firing: KLIMAZIEGPROD tests hydrogen in tunnel kilns

The brick industry in Germany produces around 1.74 million tons of CO₂ annually. Completely replacing natural gas as a fuel—for example, with hydrogen obtained from renewable sources—would enable a CO₂-free firing process and potentially avoid almost 1.09 million tons of climate-damaging gas.

In the KLIMAZIEGPROD research project, scientists convert a burner group in an existing tunnel kiln to run on up to 100 percent hydrogen and investigate the brick products manufactured in that pilot furnace. Their goal is to identify potential interactions and influences on the firing process and the quality of the ceramic materials. They aim to derive a practical concept for the most continuous possible kiln operation for coarse ceramic building materials such as roof tiles or clinker.

The hydrogen creates a water vapour-containing kiln atmosphere, which makes it possible to lower the firing temperature. Initial tests show that backing bricks fired with hydrogen have around 15 percent higher compressive strength than bricks fired with natural gas at the same temperature. The amount of burner air is also reduced because hydrogen requires less air for combustion than natural gas. This means that less air has to be heated in the furnace chamber. Using hydrogen can therefore save additional energy. In tests in a chamber furnace that can be heated with natural gas and hydrogen, the hydrogen fires required around seven percent less energy.

For industrial practice, proof of positive effects on the firing process is particularly important. At the same time, it is important for companies to contribute to the research. That way they are able to respond to customer requests – for example, regarding the colour of the bricks, which range from anthracite to “brick red.” In the KLIMAZIEGPROD research project, the scientists are therefore also paying attention to these parameters in the firing process. Once the project is completed, the results are to be put into practice at one of the project partner’s factories. The researchers are also aiming for an industry-internal and cross-industry transfer of knowledge to other building materials.

Hybrid-FIRE: Low-CO₂ hybrid furnace technology for ceramics and steel

In the manufacturing process for ceramics, the sintering process accounts for around 70 percent of total energy consumption. Other industries such as cement production, lime burning, and iron and steel production also face the challenges of high energy consumption and high levels of CO2 emissions due to the many thermal processes involved.

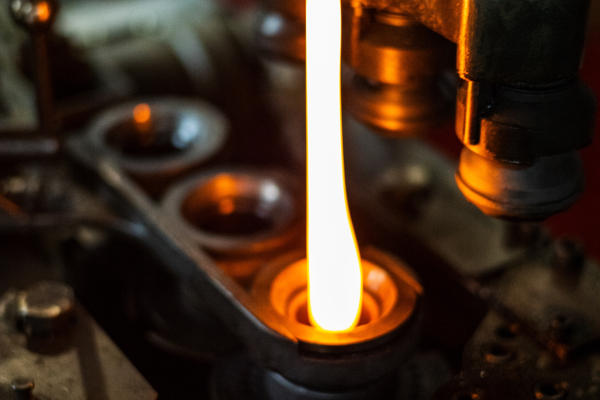

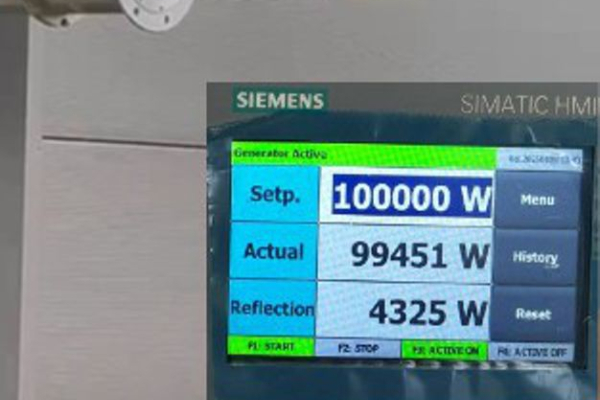

In the Hybrid-FIRE research project, a team is therefore looking at the firing process for two product groups. The researchers are developing a hybrid furnace for mass-produced ceramic products and steel melting that enables largely CO2-free treatment. The basis for this is to be environmentally friendly hydrogen and electrical energy. The hydrogen replaces the natural gas previously used in a conventional burner, which is additionally combined with one or more microwave plasma burners.

During the project, the researchers will design and build a demonstration furnace, which they will then test extensively with the various product groups. The findings will also be tested under industrial conditions by two project partners in the fields of refractory production and steel casting. They expect the hybrid technology to increase energy efficiency in both areas by at least 15 percent.

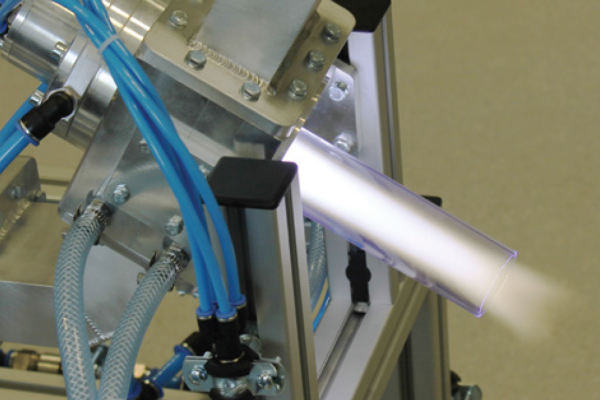

In this project, too, the changing or fluctuating amount of water vapour or the hydrogen-containing furnace atmosphere is one of the major challenges. The researchers are therefore investigating the influence this has on the overall efficiency of the thermal process and the extent to which it needs to be adjusted to protect the refractory lining used in the furnace and the workpieces from thermal shock. The plan is for the hydrogen burner to take over the preheating and for the microwave plasma burner(s) to enable the actual sintering or melting.

A major advantage for later practical application is that the microwave plasma burners can be attached to existing systems and are therefore highly compatible. They also have a flexible, controllable burner torch with high efficiency. With around 770,000 tons of ceramic products manufactured in Germany each year, the energy and CO₂ savings are likely to be correspondingly high. The situation is similar in steel production—extrapolated to the whole of Germany, the researchers have calculated energy savings of over three gigawatt hours.

H₂-DisTherPro: Producing packaging steel with green hydrogen

In the production of food cans, packaging steel undergoes several heat treatments. The recrystallizing annealing process, which is usually carried out with natural gas, is particularly energy-intensive. In the H₂DisTherPro project, a research team is developing a concept to gradually convert this process to hydrogen. Researchers are investigating how much hydrogen can be added to natural gas without having to make any design changes to the plant and what is necessary to enable operation entirely with hydrogen.

The researchers in H2DisTherPro are taking a closer look at the physical and combustion properties of hydrogen compared to natural gas. This involves, for example, requirements for the supply pipes, the necessary gas quantities and sufficient gas pressures, as well as changes in combustion properties such as flame velocity and flame temperature, which affect the burners and heat transfer. The higher water vapour content in the combustion gas is also an issue here, as it changes the heat transfer in the process. In addition to flawless process control, another challenge is ensuring the desired product quality.

With the H2DisTherPro research project, the team is gaining important insights into how to operate discontinuous thermal processing plants with lower CO2 emissions in the future and convert the steel industry to a climate-friendly alternative. The research team estimates that a complete switch from the bell annealing process to green hydrogen could save almost 50 gigawatt hours of energy nationwide each year, in addition to reducing CO2 emissions.

Hydrogen in thermal process engineering: common challenges, transferable solutions

The four projects presented show that green hydrogen and renewable electricity play a key role in a climate-friendly process industry. Although the products are diverse and the processes vary in detail, the challenges and solutions for industrial thermal processes are similar: changed furnace atmospheres, material compatibility, efficiency issues, and process stability. The research projects address these interfaces between innovation and industrial feasibility and deliver transferable solutions. This not only generates new knowledge, but also lays the foundation for scalable, climate-friendly industrial production. (ln)