© centrotherm / Lea Zeine

© centrotherm / Lea Zeine

Photovoltaics

Hydrogen makes solar cells more efficient

It inhibits the loss of free charge carriers by blocking chemical complexes and preventing recombination at the surfaces.

These are effects which the project partners, under the coordination of the company Centrotherm, fundamentally investigated within the Upgrade Si-PV project. "We have brought together two project ideas here, both of which are based on the use of hydrogen," explains project manager Dr Thomas Pernau: "Solar cell regeneration and surface passivation". The approaches are now being pursued in various follow-up projects.

Optimised regeneration furnaces are a directly utilised result when it comes to regeneration. Here hydrogen is used to inactivate chemical complexes such as boron-oxygen complexes. These are activated by light and can cause the destruction of free charge carriers. However, they are harmless when inactive. In the second project approach, the project partners used hydrogen-containing layers to passivate the cells on the surfaces. There, hydrogen prevents the free charge carriers from recombining, which would cause them to be lost. They carried out special research on methods for TOPCon solar cells. Instead of metal contacts, TOPCon cells use a full-surface rear contact consisting of a thin silicon layer and ultra-thin tunnel oxides. The load carriers can "tunnel" through these, so to speak.

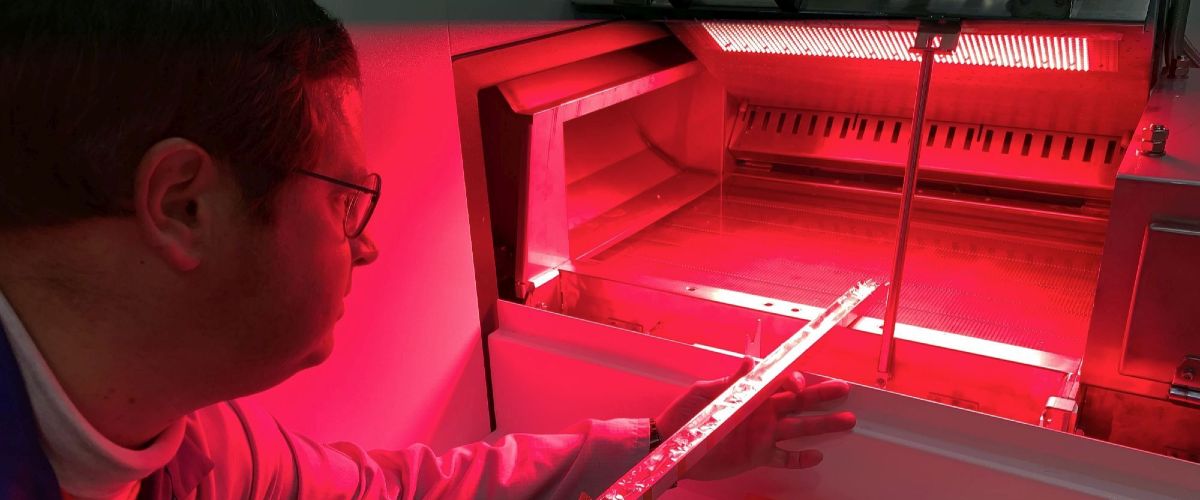

Targeted coating by ignited plasma in the PECVD method

To transfer the hydrogen to the cells, the project partners used the PECVD method. Here, layers are created by introducing the constituents in gaseous form and separating them from this gas. In contrast to thermally activated coating methods, PECVD, short for "plasma-enhanced chemical vapour deposition", ignites a plasma, which means it works with charged particles that can be directed through an electric field. "In other words, with a solar cell that has a front and rear side, I can make each side exactly as it should be," says Thomas Pernau. There is no need to remove a parasitic layer from the other side afterwards, a saved step in production. According to Pernau, current considerations are now focusing on moving the TOPCon layer with its passivating and conductive effect to the rear: "This means that the solar cell has all contacts on the rear side and there is no interference with the light input on the front." He sees a clear advantage of the optimised PECVD method in its familiarity among cell manufacturers: "It is almost the same machines, it is the same process gases, the user's inhibitions are low."

Thomas Pernau sees good future prospects for the use of PECVD: "Another thing I see coming, in a range of roughly three to five years: We will even be able to run PECVD locally. It will boil down to this."