© Peter – stock.adobe.com

© Peter – stock.adobe.com

Economical construction and operation

Controlling the sway: Investigating smarter designs for lasting wind turbines

Wind turbines are highly susceptible to vibrations due to their tall, slender structures. These vibrations can lead to long-term damage if not properly controlled. To address this, researchers are employing various strategies aimed at better understanding these vibrations and how to manage them.

One of these efforts focuses on using digital technologies to monitor turbines more closely. The RealTimeWT-Tower project, for instance, has created a digital twin of a real wind turbine from project partner Nordex. "This multi-body simulation model allows us to monitor the reference turbine in real time," says Stefan Witter, who is coordinating the project at RWTH Aachen University. To make this possible, the project team equipped the turbine with numerous measurement sensors, enabling them to validate their models and calculation methods. The goal was to predict turbine vibrations and detect potential damage to the tower early on. "Ultimately, our research will help increase the economic efficiency of the turbines," says Witter, for example by optimising maintenance and adapting the turbine's operating time based on actual fatigue-related damage. Until now, wind turbines have been designed using precautionary assumptions to ensure safe construction and operation. Using real-world data, the operating time could be extended and maintenance costs reduced.

Strategies against vortex-induced transversal vibrations

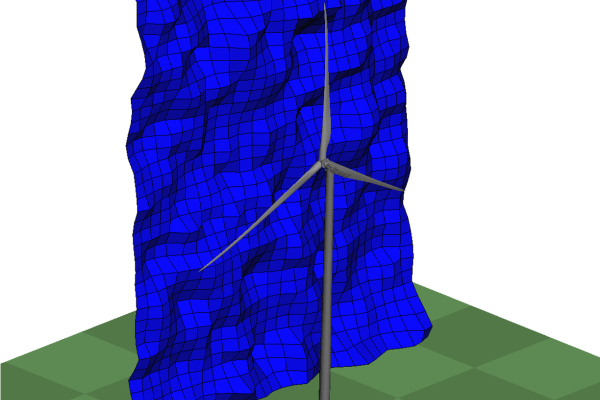

Another part of the project involved wind tunnel tests on smaller wind turbine models. Among other findings, the mechanical and civil engineering experts discovered that atypical vortex-induced transversal vibrations (explained in the info box) can occur in certain turbine configurations. This phenomenon only occurs when the rotor blades are stationary and positioned at a certain angle to the tower. The researchers also observed these atypical vibrations in the wind tunnel at higher wind speeds. The follow-up project, SenSPhWT - a collaboration between RWTH Aachen University and Nordex, will now investigate this phenomenon in greater detail.

Vortex-induced vibrations are currently difficult to predict. There are not enough full-scale measurements to capture all the relevant parameters. Relying solely on wind tunnel tests does not work due to fundamental physical limitations. To accurately calculate the vibrations, researchers need the correct Reynolds number – a value that differs significantly be-tween real turbines and the much smaller models used in wind tunnels. Although the same wind may hit both, the structures are different, causing the vortices to behave differently and resulting in different types of vibrations. "We have been struggling with this for 50 years," explains Robert Fontecha, a civil engineer at RWTH Aachen University. "There are different strategies – but we need the real parameters from an actual turbine, a numerical simulation or a combination of both."

© University Bremen / Hannah Lukoschat 2025

© University Bremen / Hannah Lukoschat 2025

Given the challenges in predicting vortex-induced vibrations, the SenSPhWT project team are turning to a multi-scale approach to bridge the gap between wind tunnel models, field data and simulations. "In the field, we experience real conditions, but we can only test a limited number of variations and have few measuring points. In the simulation, we can virtually explore anything and observe everywhere – but the results must be validated. In the wind tunnel, we can also test multiple approaches, but then we face scaling issues," ex-plains Stefan Witter. In this multi-scale approach – commonly used in the aerospace industry – data from the wind tunnel feeds into the simulations, which are then validated against the tunnel models. The validated simulations are subsequently scaled up to match the actual size of the turbine. "This allows us to identify in advance which tests are most worth-while," says Fontecha.

Scruton coils: A solution to high vibrations?

To explore potential solutions to high vibrations, the SenSPhWT project team is investigating the use of Scruton coils (explained in the info box), which are designed to reduce tower vibrations. They are already being used in the construction of new wind turbines. As long as the tower is free-standing and without the nacelle – which weighs several tonnes – it is particularly susceptible to vibrations. Scruton coils are intended to minimise these vibrations. SenSPhWT will now provide more precise, qualitative data on this: Under what conditions are the coils most effectivel? And at what point do they simply increase the diameter of the tower without reducing vibration amplitudes? Another aspect being explored is whether it would be beneficial to leave the Scruton coils on the turbine after construction. Can the atypical transverse vibrations, observed in the previous RealTimeWT tower project, be pre-vented when the turbine is stationary?

Building on previous research, the REFINE research project has already made significant strides in understanding the properties of the Scruton coil through measurement campaigns on real turbines. The research team from the University of Bremen and Nordex aimed to gain a better understanding of turbine vibrations in order to counteract them effectively. To achieve this, they gathered extensive data from measurement campaigns conducted in Spain and Croatia, among other locations. "The Scruton coil has proven to be a promising aerodynamic solution for erecting the towers," says Stephan Oelker, head of the department at the University of Bremen and project leader of REFINE.

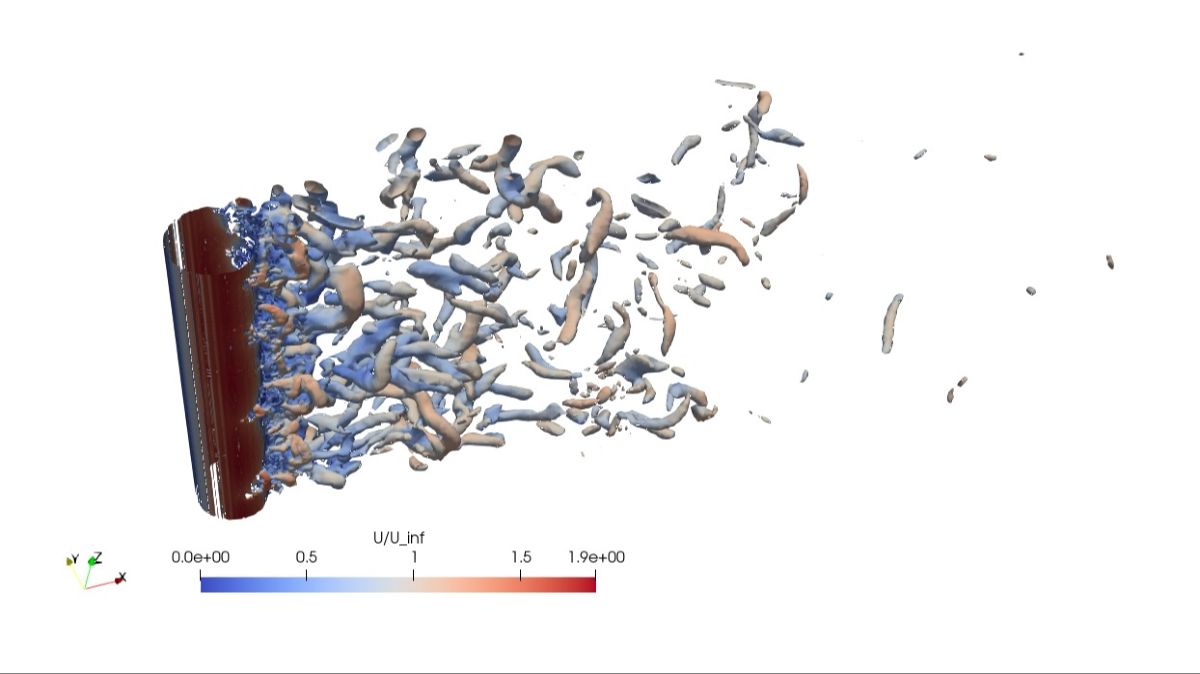

The team measured tower oscillations using a specifically developed Motion Sensor Box (MSB). The prototype was successfully tested both in the laboratory and in the field, with a small batch of 20 units produced. At the same time, they measured the fluid mechanics – both the incoming and outgoing wind – using LIDAR systems. Additionally, the researchers developed a simplified simulation model capable of predicting the interactions between the fluid (in this case, air) and the structure (the tower) at Reynolds numbers close to those encountered in real-world applications. This enabled them to successfully demonstrate the separation behaviour of vortex-induced transverse vibrations.

More flexible installation times significantly reduce costs

In addition to their technical benefits, the researchers also assessed the economic impact of using Scruton coils. They focused on how these coils could reduce installation costs and improve overall cost-effectiveness during the construction phase. Wind turbines are assembled piece by piece from multiple segments. If vibrations are too high, Nordex addresses the issue by taking breaks or, in some cases, dismantling parts of the structure. When assembling the uppermost and most fragile segment of the tower, the wind must be at low speeds. This creates narrow time windows and extends construction times. "If we can expand the permissible wind speed range with the coils, for example from 5 metres per second to 8 metres per second, this will have a significant impact," explains Oelker. Fewer breaks and a shorter construction time enhance the cost-effectiveness of the entire system. To quantify this, the researchers analysed wind data across the entire European Union, available via the New European Wind Atlas. They used the data to create specific wind scenarios, which helped assess the potential of these aerodynamic devices. The key question was to what extent this could increase the installation of new turbines. The researchers have published their preliminary results at WinterSim (mb).