© InES / THI

© InES / THI

Bioenergy

Biogas ensures stable networks

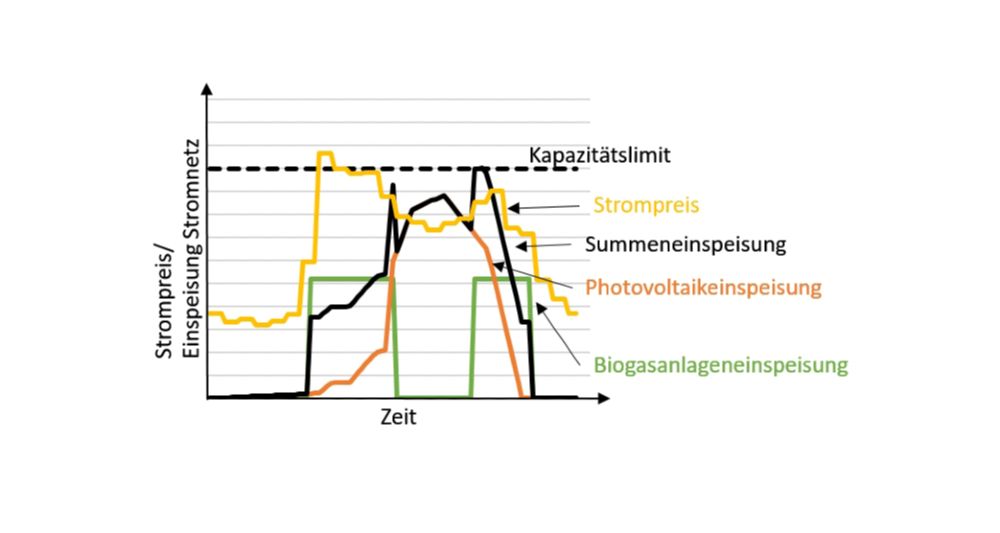

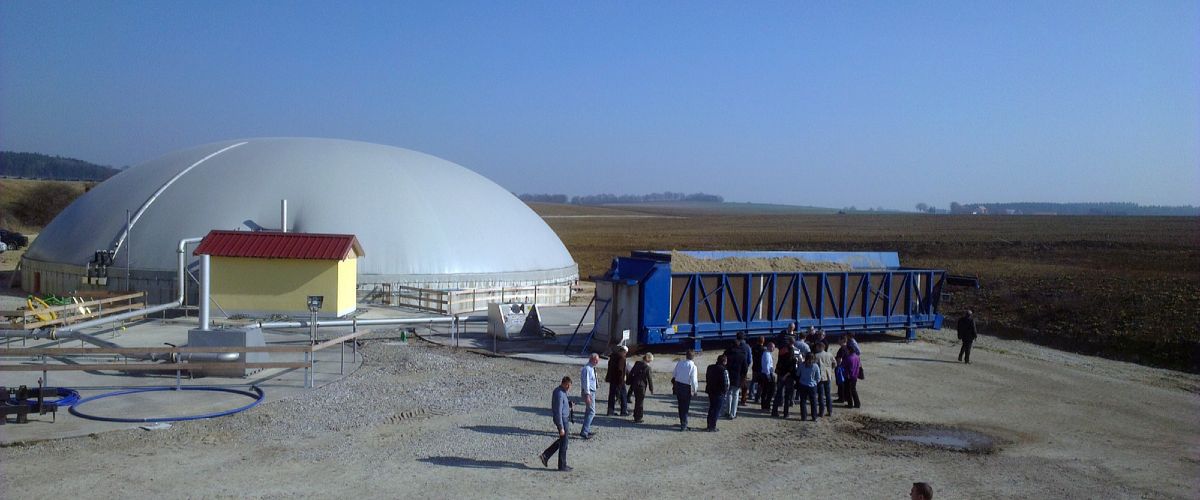

Biogas plants can flexibly feed in power and heat and in this way compensate for fluctuations. In the FlexFuture research project, scientists developed a biogas plant control system for demand-based electricity production. The control system can create schedules for cogeneration plants based on the electricity market, heat demand and distribution network. These schedules enable generation and grid congestion management that also keeps an eye on the overall efficiency of the biogas plant. At the Zellerfeld biogas plant, it was successfully demonstrated that congestion and overloads in the power grid can be avoided if photovoltaic and biogas plants feed in power in a coordinated manner.

Project context

The increasing share of renewable, fluctuating energy generators, such as wind power and photovoltaics, is already pushing distribution and transmission networks to the limits of their physical performance capability. Particularly the requirements for distribution grids with regard to operation and protection mechanisms are becoming increasingly complex. Congestion must therefore be expected in the future, especially in these networks. Operators are meeting the challenges with load balancing, peak load capping, grid expansion and the use of electricity storage facilities. These measures are both planning and cost-intensive. A promising alternative is controllable, decentralised electricity generation by biogas plants, adapted to the local needs of the distribution grids.

Research focus

Biogas plants can reduce their electricity production during periods of low residual load and supply electricity generation capacity during periods of low infeed from fluctuating electricity generators. During demand-based operation, the total amount of electricity generated in the biogas plant remains constant compared to a biogas plant in continuous operation. So far, timetables for biogas plants have been based mainly on electricity prices.

The aim of demand-based control is to take into account the daily and maximum infeed profiles of adjacent photovoltaic systems on a regional basis. The Zellerfeld biogas plant and the Wolfsgrube open-space photovoltaic plant with a total of 6,438 kilowatts of electrical feed-in power are connected at the Zellerfeld grid connection point (GCP), with a capacity of 5,000 kilowatts of electrical power. This means that on sunny days the feed-in power of the two plants exceeds the AC-side power switch limit of the medium-voltage distribution network. In this case, all plants are disconnected from the power grid. This is due to the output limit on the GCP.

In the course of the project, the research teams developed control concepts for the operation of biogas plants with the support of the Zellerfeld biogas plant and the Lechwerke distribution grid. These support the distribution grid in order to compensate for short-term fluctuations in the power grid via the controllable power production of the biogas cogeneration plants. Daily weather and irradiation forecasts are used for this purpose.

Innovation

The flexible operation of biogas plants depending on the power grid is a novelty. The heart of the control system is the control unit. In addition to the daily electricity price of the European power exchange EPEX SPOT SE, the control unit takes into account weather and irradiation forecasts and the resulting maximum possible PV feed-in power into the local grid as well as the current biogas storage tank filling level of the biogas plant. The overriding goal of maximising the turnover for biogas plant operators is incorporated into the 32-hour timetables that are to be drawn up for the cogeneration plants.

The system includes other parameters such as the performance capability of the cogeneration plants and the internal (biogas plant) and external (local heating network) heat demand. This allows the biogas plant operator to maximise turnover at the same time, despite the fact that the cogeneration plant is operated in a grid-friendly manner.

Results

"We have shown in real operation at the Zellerfeld biogas plant in Bavaria that electricity peaks in the infeed of renewable electricity can be avoided by using an intelligent plant control system," explains Prof. Wilfried Zörner, project manager at the Institute for New Energy Systems at Technische Hochschule Ingolstadt. The developed schedules for the control of the biogas plant take into account the regional requirements of the power grid and thereby enable grid-friendly operation. This makes it possible to integrate larger shares of fluctuating renewable energy generators into the distribution grid.

Monitoring of the test system, the Zellerfeld biogas plant, allows an economic evaluation in a specific case and shows the potential of the control system for broad application.

Practical transfer

The developed, controllable electricity generation with biogas plants promotes, in addition to grid support and relief, the increasing phase-out of power from fossil energy media. The technology can not only be transferred to biogas plants operating in Germany, but can also be used with little effort in all plants with flexibly operable cogeneration plants. Biomass CHP plants, sewage gas plants and natural gas cogeneration plants are suitable for this purpose.