© Jan Cremers

© Jan Cremers

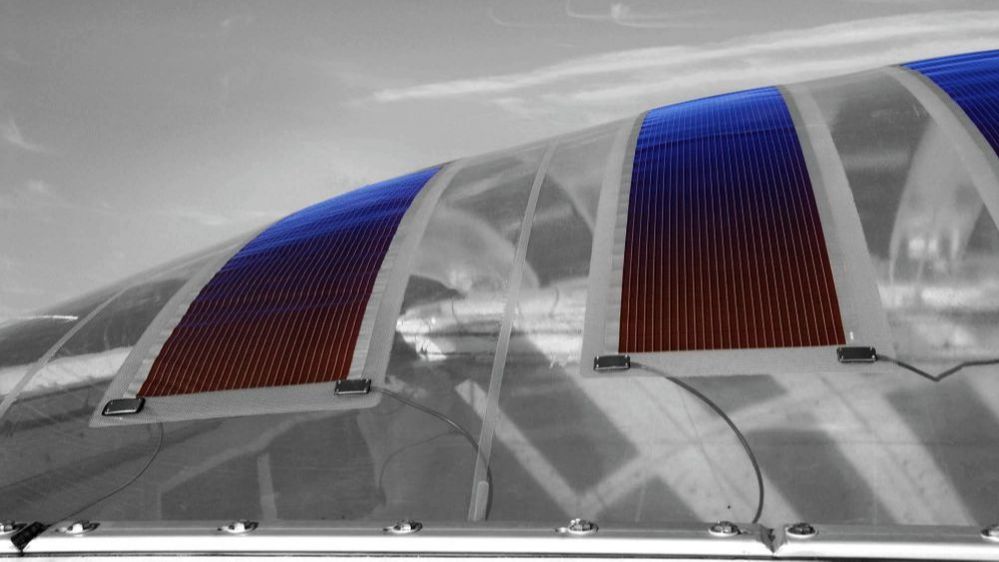

Textile membranes

Lightweight and flexible envelopes as functional building membranes

Buildings can be optimised in terms of their energy efficiency using new, lightweight and flexible structures made of films or textile fabrics. The functional properties of membranes are being optimised and innovative components and systems developed, such as surface functionalisation with low-e coatings, to improve the thermal insulation. The solutions developed are also intended for enclosing courtyards and atria. Here the thermal flow conditions and daylight situations in the atrium and adjoining rooms need to be taken into account.

The Allianz-Arena in Munich and the Water Cube in Beijing offer a spectacular demonstration of the new capabilities of textile architecture. In the EnOB research project “Development of low-emissivity coatings in textile architecture”, sheeting, fabrics and membrane constructions are provided with a special coating that makes a significant improvement to their thermal properties. These are referred to as low-e coatings, which emit little heat and reflect incoming thermal radiation well.

As part of a new research project “Membrane constructions for the energy-oriented refurbishment of buildings” (MESG), the aim is firstly to develop new concepts in order to achieve significant energy savings for buildings in Germany through the use of sheeting or fabrics in refurbishment projects. This involves heating energy as well as cooling and lighting energy. Secondly, such concepts can also contribute to energy optimisation in new buildings.

© Jan Cremers

© Jan Cremers

Research focus

Since then, advances in material research, engineering know-how and computer technology for handling the complex geometric parameters and the spatial assessment of the flow of forces and load-bearing behaviour have significantly expanded the application areas of membranes as building envelopes. New powerful planning tools that can capture and process the membrane surfaces geometrically in three dimensions make their use economically feasible and are controllable in both planning and production terms.

In the current research project, first of all a typology for the application of membranes in building envelopes will be developed. The main task consists in combining structural, functional and design requirements. Building on this, the functional characteristics are optimised and new kinds of components and systems are developed. Standard solutions are created which are used as modular components and systems. The aim is to install them in demonstration buildings and investigate them further.

As well as optimising the functional characteristics of membranes, above all the aim is to develop new kinds of components and systems. Individual components that are already available on the market are combined into new and innovative systems. Improved components are also developed and tested. The aspects of thermal insulation, energy storage and the buffering of heat peaks, passive and active (thermal) solar energy usage and the generation of electrical energy are to be worked on in detail.

© Jan Cremers / Hightex GmbH

© Jan Cremers / Hightex GmbH

In addition, an interdisciplinary approach is being pursued as part of the project. As well as the individual components, this will also look at their integration into the building and the control concept that is necessary for the heating and/or climate control system. For example, an increase in thermal mass with simultaneous reduction of the response time of the building’s control system is desirable in order to enable an optimum control strategy in respect of ventilation, heating and cooling.

Successes

To date, functional surface coatings have been developed that reduce heat emission into the environment. Low-e fabrics of this kind can significantly improve the thermal insulation of membrane constructions, thereby contributing to increasing energy efficiency in the building. At the same time it has become possible to combine the low-e characteristic with any desired colour effect, which yields flexible architectural design possibilities.

A further aim of the project is to prepare a pilot application and implement individual innovations and developments in connection with real buildings after the project ends.

Application

The scientists developed a concept for an inner courtyard roof for two buildings at the HFT Stuttgart and the TU Munich. One focus of the research was the thermal flow conditions as well as the daylight situation in the atrium and the adjoining rooms. The results show that ventilation options must be provided via the membrane roof, as the interior temperatures in summer rise steadily with height. Cushions that can be moved upwards are an option here. Depending on the lifting height, a variable opening width is created. A sufficient number of adjustable air inlets ensures the necessary air exchange.

The daylight situation depends on the geometry and size of the covered courtyard. In the case of the HFT Stuttgart, the small and tube-like area of 400 m2 of roof surface means that the adjoining office rooms are no longer supplied with sufficient daylight from a room depth of 2 metres. In Munich, with a covered area of 1,300 m2, the offices have sufficient daylight.

The climate concept places high demands on the building services. The atrium behaves like an air collector. The air temperatures vary greatly depending on the air exchange and solar irradiation.

Compared to a glass roof, a membrane construction has a clear primary energy advantage. This is due to the lower material consumption for the supporting structure and the roof cladding. As an example, the primary energy demand for both a glass and membrane construction with cushions was calculated for the project in Munich. The energy demand for the membrane roof is approx. 50% lower.