© TU Kaiserslautern/IZES gGmbH

© TU Kaiserslautern/IZES gGmbH

Renovation of existing buildings

More renewable energy with sandwich elements

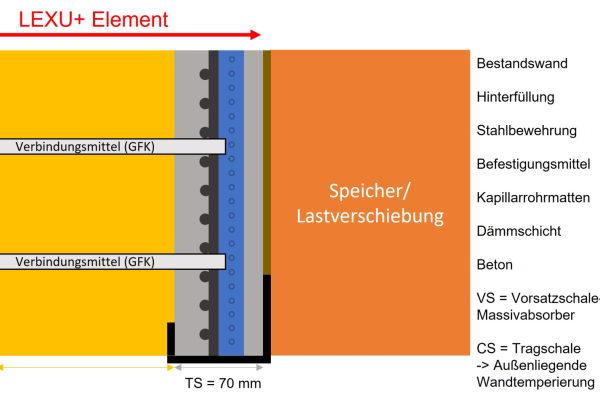

Installing underfloor heating in an occupied building is very expensive. So why not use the exterior wall as a surface heating system? Combined with a sandwich facade element, this can additionally gain and store environmental energy and insulate the building – as the LEXU_PLUS project shows.

Prefabricated sandwich facade elements are designed to help increase the use of renewable energy in existing buildings. Sandwich elements are facade components that consist of several layers and are mainly used for building insulation.

In the recently completed LEXU_PLUS project (development and testing of innovative prefabricated sandwich facade elements for the holistic low-energy temperature control of existing buildings, utilising the building structure), the project partners combined the new elements with a thermally activated external wall. The research team had already developed this in previous projects. In the case of thermal component activation, the building structure is used for temperature control and storage.

Since the transfer surface is very large, the heat transfer medium in such a surface heating system does not need to be heated as much as in conventional heating systems. In addition, a large thermal storage mass is available. Heat generation and consumption can be better decoupled in terms of time. This not only makes it easier to integrate renewable energies into the system, but also to use low flow temperatures of 25 to 30 degrees Celsius or less.

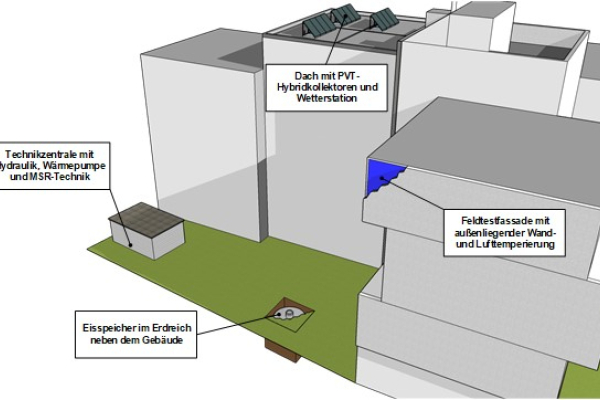

Sandwich facade element tested on two demonstrators

The developments and testing of these sandwich facade elements have been tested by the researchers under the direction of the Institute for Future Energy and Material Flow Systems (IZES) in Saarbrücken on two demonstrators. There was one advantage over the previous project: the new facade system no longer has to be completely implemented on site. In the previous projects, the system of the thermally activated exterior wall was implemented by different trades. This led to many interfaces and high costs. With the new sandwich elements, the process is simpler. The components can be prefabricated in the prefabrication plant and only have to be attached to the existing wall on site.

The researchers have tested the new sandwich element in two demonstrators. It was thermally analysed under real-world conditions at the Rhineland-Palatinate Technical University of Kaiserslautern-Landau. Experts tested the installation of the element on a facade at project partner Komzet Bau Bühl in Baden-Württemberg. The tests showed that the elements can be mounted on an existing wall, insulate the building and control its temperature, and can also be dismantled and recycled.

New connecting element for lower heat conductivity

The prefabricated sandwich facade element developed and examined in the project is a component made of two reinforced concrete shells arranged parallel to each other, the facing shell and the load-bearing shell. These are coupled together by evenly distributed, rod-shaped connecting elements. Between these two shells is an insulation layer that can be freely selected in terms of thickness and material. The shells are connected by means of the newly developed rod-shaped connecting elements made of glass-fibre reinforced plastic (GRP). The advantage of the material used for the connecting elements is that, unlike steel, it is not subject to corrosion. It also has low thermal conductivity, which enables the two concrete shells to be connected with virtually no thermal bridging, thus ensuring an energy-efficient connection.

New facade element provides additional environmental heat

Overall, the new sandwich facade element is a multitalented product: it can generate and store energy, insulate and temper adjacent rooms. This is done by means of an innovative heat exchanger system that can be attached to the outer wall regardless of the type of building and makes the building structure usable as a storage medium. This means that renovation using the new sandwich elements is also possible in occupied buildings. The new element is designed to capture additional environmental heat via integrated solid absorbers. The heat from the surrounding air and solar radiation that hits the facade is stored and can be used for heating in combination with a heat pump.

The project consortium is currently working on bringing this minimally invasive renovation option to market. To do this, the manufacturing costs must first be reduced and the overall system made more efficient.