© Baker Hughes Company

© Baker Hughes Company

Geothermal energy

Software system automatically monitors drilling process

Drilling safely into the depths is generally associated with many technical uncertainties. This makes it difficult to meet the time and cost schedules that are drawn up at the beginning of a project for the economic efficiency analysis. Engineers have therefore developed a modular software system that automatically monitors all aspects of the drilling process and optimises them during drilling. This concerns the borehole hydraulics and borehole cleaning, the static and dynamic stress on the drilling equipment and the drill string as well as the placement of the borehole. This automation is intended to optimise the borehole design in terms of both safety and time.

Monitoring the entire drilling process

Currently, the drilling process is typically permanently monitored by several engineers, each specialised in one aspect, using a large number of measurement values, which are compared with a drilling plan and optimised. For example, they control the stability of the borehole and the debris discharge, meaning the amount of drilled rock that is brought to the surface as crushed or fragmented material. They also monitor the static stresses on the drill string and drill assembly. Furthermore, they keep an eye on vibrations, which not only have a negative impact on the lifetime of the drilling tools but can also make precise underground measurements difficult and slow down the drilling progress.

The newly developed automated process monitoring system reliably identifies deviations from the plan as well as unforeseen events. This allows the drilling process to be continuously adapted to the measurement values and in some cases even to predictions about the drilling process derived from these. Engineers can therefore have a complete overview of the drilling process, keep an eye on the safety of the operations and control them proactively, instead of having to interpret individual measurement values.

New software modules monitor the drilling process

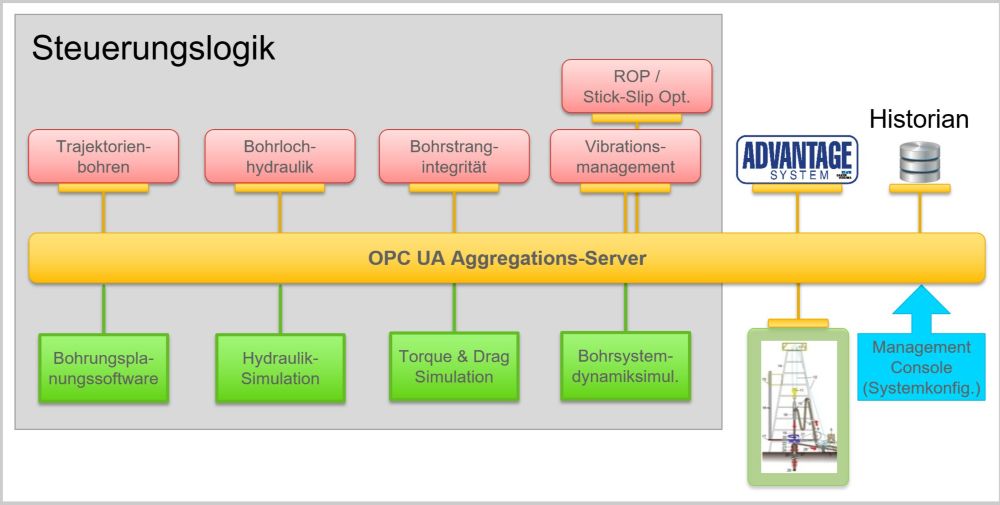

Based on the results of the AUTIG research project, the project team has developed individual software modules within AUTIG_BPEO, short for "Automatable Drilling Technology for Deep Geothermal Energy - Drilling Planning and Real-time Optimisation". These can automatically monitor and in some cases also control the drilling process. The modules follow the system architecture developed in the AUTIG project and communicate exclusively with the aggregation server as central data storage. Each module represents an aspect of the drilling process, such as the control of the directional drilling tools, the monitoring of the borehole hydraulics, the static and dynamic stresses on the drill string and the vibration management. Processes taking place in parallel are also observed and optimised holistically.

When planning a borehole, engineers use computation-intensive mathematical methods to simulate the drilling process. The automation software now uses the same methods in a modified form to monitor the drilling process in real time. This results in so-called digital twins or algorithms that are used to predict individual aspects of the drilling process. These represent a real object in the digital world. The two worlds are linked by sensors. Real-time measurement values are used to permanently adapt the twins to the real process. In the course of the project, the functions of the individual methods of drilling planning were extended and optimised for real-time calculation. This makes it possible to draw detailed conclusions about the properties of the process along the borehole at any time, even though only measurement values from sensors at the end of the drill string and from the surface drilling rig are available. This means that forward-looking statements are also possible.

Horizontal boreholes for geothermal heat exchangers

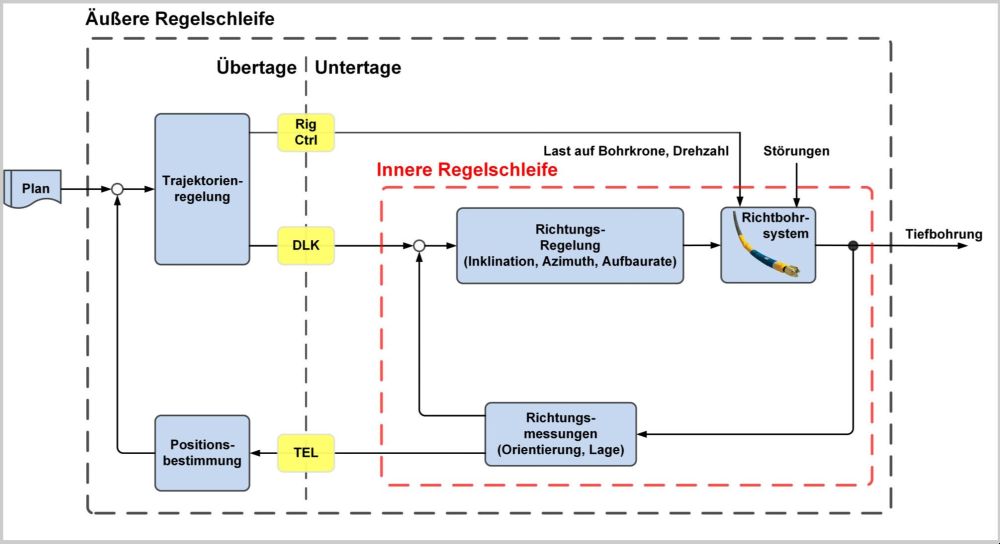

Predicting the expected position of the drilling set allows the drilling plan to be followed by proactively controlling the directional drilling tool. This is important for geothermal heat exchangers, for example, where two exactly parallel horizontal boreholes are created. These are connected by cracks in the rock. If the directional drilling tools can be controlled automatically, efficient and accurate drilling is possible. In addition, the engineers have improved the methods to determine the borehole direction and position of the drilling tool. The resulting overall system of accurate directional measurement and control can precisely

First tests were successful

The project team has already successfully drilled the first boreholes on a test system of Baker Hughes. The results have confirmed that the new software modules reliably control the drilling direction, monitor the process and raise an alarm in case of events. This means that the directional driller only needed to monitor the drilling process.

Commercially usable software is in the starting blocks

The prototypes of the software modules developed in the AUTIG_BPEO project can be used for tests in geothermal boreholes. The first versions of a commercially usable software system that includes all modules are already available.

The project team is also continuing to research new algorithms in order to continuously expand the functional scope of commercial software and improve its performance capability.