© eyetronic – stock.adobe.com

© eyetronic – stock.adobe.com

Turbomachines

Microturbine becomes hydrogen-capable

Euro-K is working with TU Berlin to develop a burner that can be installed in commercially available turbines and run on 100 percent hydrogen.

Microturbines are the small but autonomous sisters of large gas-fired power plants. Their advantage is that they produce electricity and heat directly where the energy is needed. This can be in hospitals, administrative buildings or in emergency units for disaster areas. Thanks to their compact design, they also require little space. They require little maintenance and are efficient.

Up to now, microturbines have been operated mainly with natural gas. But this is set to change in view of climate change and the emission reductions this will require. The company Euro-K, for example, is researching an alternative together with the Technical University of Berlin. In the H2mGT research project, the medium-sized company from Cottbus and the university are developing a burner that can run on 100 percent hydrogen. Following laboratory and test trials, the developed design including technology is to be installed in a marketable micro gas turbine from Euro-K and is expected to be available for purchase in two to three years. The Cottbus-based company is initially focusing on its use as a stationary power unit and in hybrid commercial vehicles as an alternative to the internal combustion engine.

"Staged air supply ensures homogeneous combustion process"

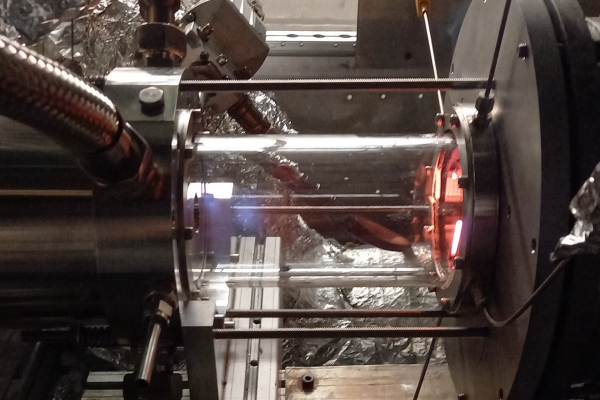

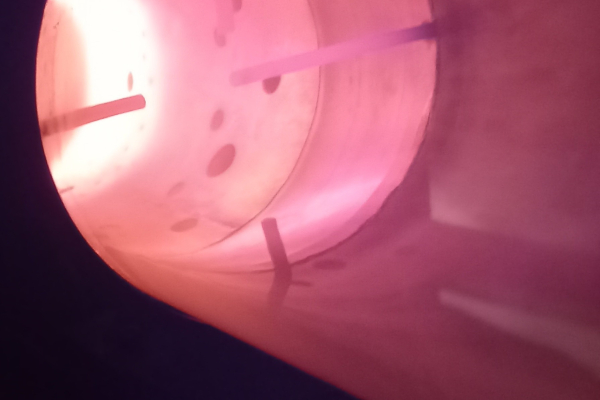

The collaboration between the university and the company is going well. "The TU Berlin was responsible for the basic design of the burner. It now works well and stably on a laboratory scale. The burner is currently undergoing some reconfiguring so that we can integrate it into our micro gas turbine," reports Johannes Mundstock, project engineer at H2mGT. After that, the test cycles will be carried out on the Cottbus test rigs. If everything goes according to plan, this will be the case in early summer 2023.

With 100 percent hydrogen as fuel, the operating behavior of the turbine changes. What has already been tested and optimized on a laboratory scale must now be further fine-tuned in actual operation. "The challenges include, for example, keeping the flame centered in the burner. If it hits the housing wall, this can cause damage to the wall material. Since hydrogen burns very quickly, there is also a risk that the flame will migrate upstream, i.e. pull toward where the fuel is injected," explains Johannes Mundstock. The researchers in the H2mGT project have already solved these issues . The potential danger of high nitrogen emissions has also been averted by making adjustments to the burner design. "We designed the burner with a staged air supply so that it has good burnout, so there are only low nitrogen oxide emissions," the engineer reports.

"Development always involves trial and error. That makes it rather difficult for us as an SME. That's why we are pleased that H2mGT was eligible for funding. This reduces the economic risk."

Johannes Mundstock, Euro-K GmbH, Cottbus

Once the research project has been completed, Euro-K's task will be to successfully launch the "H2-ready micro gas turbine" on the market. It is important for potential customers to have an infrastructure that supplies the hydrogen. In many countries, however, this is just being established, including Germany. "We currently have the chicken-and-egg problem with many hydrogen applications," explains Johannes Mundstock. "What comes first? The user who needs the hydrogen, or the infrastructure that supplies it? We're now getting ahead of the game with our product - with a view to a number of potential markets, initially primarily in the Asian region." (it)