Photovoltaics

World Recycling Day: Recycled silicon for new solar cells

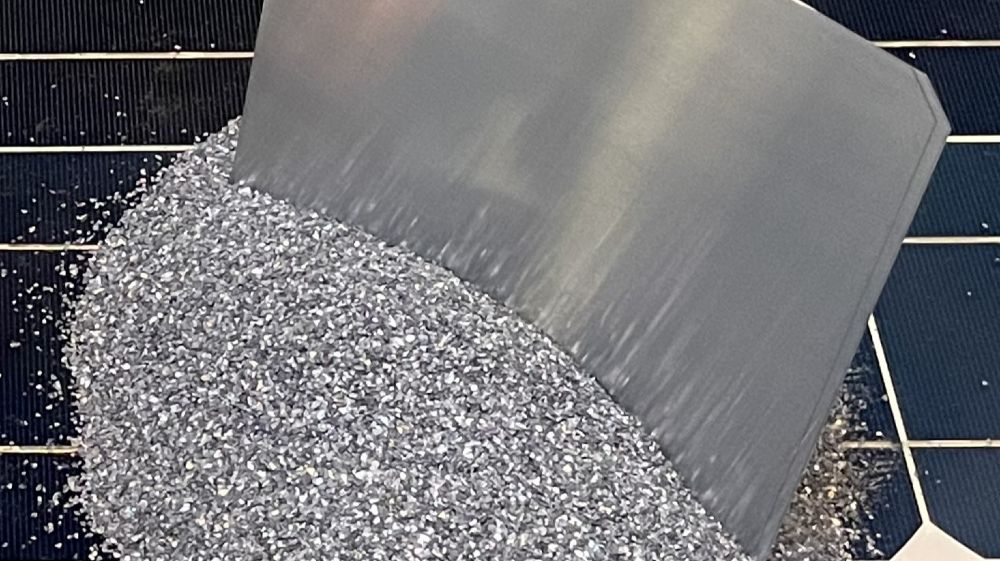

In the ReModul project, scientists have developed a method with which silicon can be recovered from retired solar modules and recycled.

18 March was International Recycling Day. At the latest since the introduction of the Dual System in Germany in the early 1990s, the term has been widely known and linked to concerns about separating and avoiding waste. In addition to the societal responsibility and public disposal, the recycling of waste products is also important for a wide range of industrial sectors - including photovoltaics. Being able to recycle materials from old solar modules after they have reached the end of their lifetime plays an important role when it comes to the energy transition and the sensible use of resources. A key raw material is the semiconductor material silicon, which is the primary constituent in solar cells used today.

New recycling method for silicon solar cells on an industrial scale

In cooperation with a recycling company, a team of scientists from the Fraunhofer Center for Silicon Photovoltaics CSP has developed a new method for recovering silicon from solar cells. What’s special: The method makes it possible to recycle any type of crystalline silicon photovoltaic module. This also makes the method financially viable for the recycling industry. The method is based on an already established processing method for silicon solar modules.

This produces by-products from which the fragments of the solar cells are first separated and collected. These fragments with a maximum size of one millimetre contain glass as well as plastic parts, which are first separated. The functional constituents of the solar cell are then removed by means of wet chemical etching. What remains is pure silicon without rear contacts, silver contacts, anti-reflective coating and emitter.

Recycled silicon for new solar cells

The material cleaned in this way can be used to produce new wafers, which therefore consist of 100 per cent recycled silicon. Researchers at the Fraunhofer Institute for Solar Energy Systems ISE have already processed these wafers into new PERC solar cells and were able to achieve an efficiency of 19.7 per cent. "This is below the efficiency of today's premium PERC solar cells, which have an efficiency of around 22.2 per cent, but certainly above that of the solar cells in the old, decommissioned modules", explains Prof. Dr. Peter Dold, project manager at Fraunhofer CSP.

In the long term, solar cell recycling is a growing market. At present, the photovoltaic modules discarded in Germany each year, which amount to about 10,000 tonnes, contain about 300 tonnes of silicon. So far, only the aluminium, glass and copper contained in the modules are recycled. Projections for the end of the decade predict that the number of retired solar modules will be many times higher: The annual volume will then be between 100,000 and 400,000 tonnes, which in turn will contain 3,000 to 10,000 tonnes of recyclable silicon.

Day of action highlights the relevance of recycling

International World Recycling Day falls annually on 18 March. The Bureau of International Recycling (BIR) represents the interests of the recycling industry as a global association and initiated it for the first time in 2018. The day of action is intended both to establish the issue in the public sphere and to raise its profile at the political level. The initiators' aim is to provide suggestions and demonstrate measures with which raw materials can be productively recycled.

In the ReModul project, researchers are addressing precisely this issue and demonstrate how recycling measures can also be successfully developed and implemented in the photovoltaic industry. In 2019, the German Federal Ministry for Economic Affairs and Climate Action (BMWK) funded the project with around 1.05 million euros. (av)