© EnBW – Uli Deck

© EnBW – Uli Deck

Geothermal energy

Thermal water as a source of lithium: Using geothermal plants for raw material production

Lithium as a constituent of rechargeable batteries is essential for the expansion of e-mobility. Teams of scientists are investigating how the coveted raw material can be extracted from thermal waters in Germany.

According to a study by the German Raw Materials Agency, global demand for lithium will double or even triple by 2025. A major driver of this development is the increasing demand for lithium batteries, especially for electric vehicles. The German government is also promoting the electrification of transport and considers the expansion of e-mobility to be an important lever for climate protection. This is because, according to preliminary estimates, the transport sector alone accounted for almost 20 per cent of total greenhouse gas emissions in Germany in 2021. To meet the growing demand for lithium, however, Germany - as a high-tech location without its own lithium production - has so far relied exclusively on imports.

Promising lithium potential in Germany

Research teams are therefore working on ways to extract lithium domestically as well. Because in some regions of Germany there is promising potential for extracting the raw material from the deep substratum. For example, in the North German Basin – a large sedimentation area stretching from England across northern Germany to the eastern border of Poland – up to 350 milligrams of lithium per litre were measured in hot deep waters of the Rotliegend Formation at a depth of about 4,500 metres. In the Upper Rhine Graben - between Basel and Frankfurt am Main - significantly elevated lithium contents of up to 200 milligrams per litre were also found in hydrothermal fluids.

A promising approach to utilising these deposits in the future is being pursued by scientists in the UnLimited and Li+Fluids research projects. They are investigating how the production of lithium can be factored into the design and expansion of geothermal plants in addition to the generation of power and heat. The advantages are obvious: Firstly, the raw material - as a by-product of power and heat production - could be obtained in a manner that is both climate-friendly and environmentally sustainable, and the economic viability of geothermal energy could be increased through the more efficient use of the thermal water. Secondly, the heavy dependence on imports would be reduced.

Wanted: Basic prerequisites for economically efficient lithium production

In the UnLimited joint project, teams of scientists coordinated by EnBW Energie Baden-Württemberg are working on creating important foundations for lithium production from hot deep waters in Germany. In various sub-projects, the researchers are investigating and evaluating the location-specific and regional sustainability and economic viability of lithium production. Their investigations include the North German Basin and the Upper Rhine Graben.

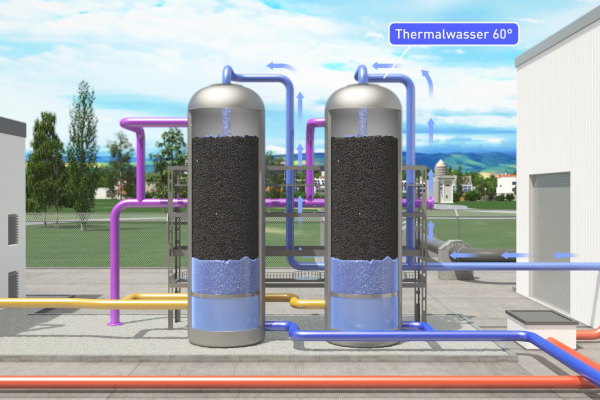

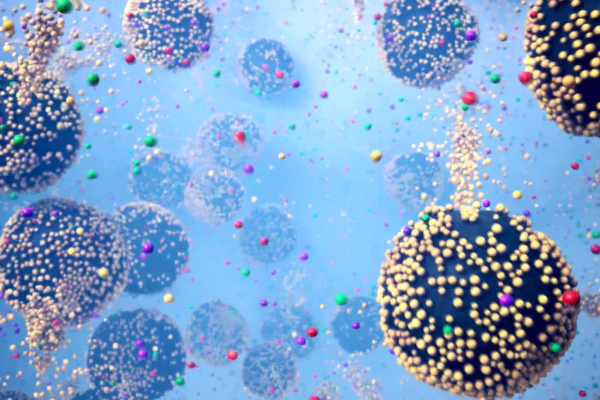

One focus of the project is the selection of suitable adsorbents with which the lithium can be extracted from the thermal waters. Adsorbents are substances which, due to their porous surface, are suitable for binding certain components from gases or liquid mixtures. To this end, the scientists are developing a monitoring system tailored to individual locations for various indicators relating to extraction. In addition to the material properties, the researchers are also interested in how the adsorption materials can be produced, used and later disposed of or recycled in an environmentally sustainable way.

At the Bruchsal geothermal power plant – between Karlsruhe and Heidelberg in the Upper Rhine Graben – the adsorbents, which are particularly suitable for lithium extraction, are finally tested in practice. For this purpose, the researchers use a pilot plant that is connected to the power plant with which EnBW already generates electricity and heat.

Decision support for designing geothermal plants

Researchers in the Li+Fluids joint project are also working on lithium production at geothermal plants. Under the coordination of the Federal Institute for Geosciences and Natural Resources (BGR), they are preparing a comprehensive study on the potential for lithium extraction from hydrothermal fluids in Germany. The results are expected to contribute to developing a strategy that can serve as a decision-making aid in the future when designing geothermal plants with power and heat production as well as additional raw material extraction.

The scientists are specifically investigating several locations in the North German Basin where geothermal plants are already in operation or where future operation appears to make sense from a geological point of view. The aim is to develop a method with which lithium deposits can be assessed systematically and comprehensively. The data obtained will be used for site selection in the future. In addition to geology, the research teams are looking in particular at the ecological and economic aspects of lithium extraction. They also assess the sustainability of production at the research sites compared to conventional lithium extraction.

At the Horstberg location – between Celle and Uelzen – practical application then begins. There, the scientists are using a BGR research well to separate lithium in the North German Basin in the first technical tests.

Cross-project cooperation

In order to efficiently advance lithium production at German geothermal plants, the UnLimited and Li+Fluids teams are also working closely together. The scientists involved already exchanged ideas intensively during the preparation of the projects. They regularly present the results achieved in status seminars and workshops and discuss them with their colleagues across projects. (lh)