© ISFH

© ISFH

Photovoltaics

Optimised coating process for tandem solar cells

In a newly launched research project, researchers want to improve the manufacturing equipment for coating silicon perovskite tandem solar cells.

Silicon solar cells are achieving ever higher efficiencies. One of the factors that made this possible was progress in materials research and improved production processes. At the same time, however, developments are also contributing to the fact that it is becoming increasingly difficult to achieve further increases in efficiency. Because these are associated with ever more technically complex processes.

An alternative and promising possibility to achieve higher efficiencies are so-called tandem solar cells. Tandem solar cells are composed of two or more layers arranged on top of each other, which again consist of different materials. This type of solar cell is more efficient due to its structure. The individual layers absorb different wavelengths of incident sunlight, which allows the cells to use a broader spectrum of light.

Producing silicon perovskite tandem solar cells

Due to their properties, tandem solar cells also offer promising potential for optimising conventional silicon solar cells. In addition to the silicon solar cell, a perovskite solar cell is also used to increase the efficiency by combining the two cell types into a tandem solar cell. The central production technique for this is called perovskite separation.

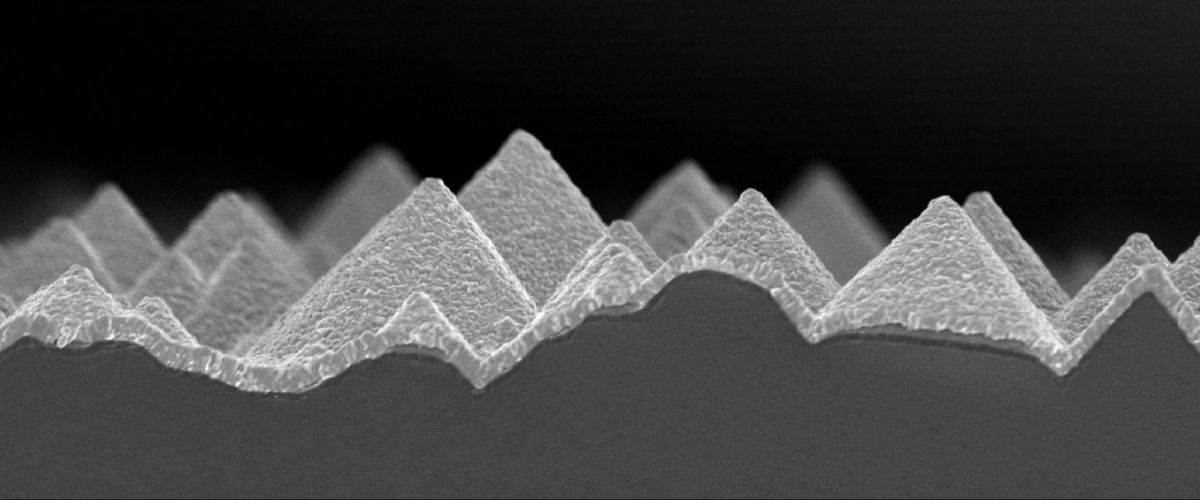

Producing a silicon perovskite tandem solar cell requires perovskite films, which are fine layers of perovskite. This requires a method with which thin and even layers can be applied to a carrier material, the substrate. Established methods already exist for this production step. Spin-coating, for example, is widely used. However, this method is only suitable for laboratory applications and not under industrial aspects.

Potential for industrial perovskite separation

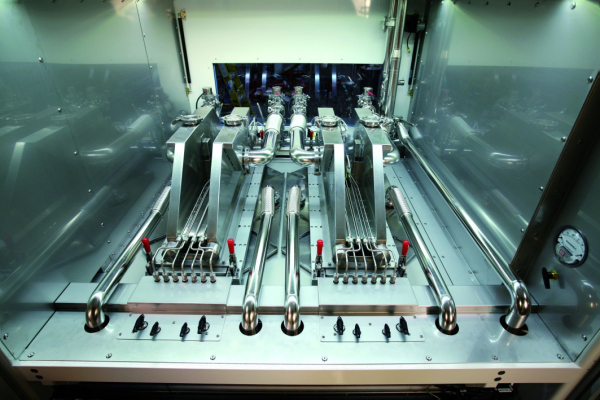

This is where the APERO research project comes in. Among other things, the team of scientists is working on the chemical vapour deposition (CVD) coating process. This method is already used for various manufacturing processes. The researchers now want to implement the method for production at atmospheric pressure. This process, known as atmospheric pressure chemical vapour deposition (APCVD), has not yet been used so far.

The production of perovskite layers at atmospheric pressure has the potential to be cheaper and more flexible than conventional methods. This is because APCVD coating systems operate entirely under atmospheric pressure, thus eliminating the need for vacuum pumps. At the same time, a roller conveyor in the system is used to heat only the substrate to be coated, which greatly reduces electricity and cooling costs. In addition, the thicknesses and composition of the deposited layers can be adjusted via various configuration options of the system. All these factors make the APCVD process a promising method for the industrial production of highly efficient perovskite films.

Expected progress using APCVD technology

APCVD technology has already been taken up in several funded projects. The focus was always on a different aspect of the technology or on the interaction with other processes. The team of scientists now wants to demonstrate that an APCVD system can be used to deposit highly efficient perovskite layers that are comparable in quality to established processes. The researchers want to evaluate different layer-forming starting materials (precursors) and investigate the quality of the deposited layers. The team of scientists wants to use this to develop a process for depositing high-quality layers for perovskite solar cells with an APCVD system.APCVD technology has already been taken up in several funded projects. The focus was always on a different aspect of the technology or on the interaction with other processes. The team of scientists now wants to demonstrate that an APCVD system can be used to deposit highly efficient perovskite layers that are comparable in quality to established processes. The researchers want to evaluate different layer-forming starting materials (precursors) and investigate the quality of the deposited layers. The team of scientists wants to use this to develop a process for depositing high-quality layers for perovskite solar cells with an APCVD system.

The research project started on 01 May 2021 and will last three years. It is funded by the German Federal Ministry for Economic Affairs and Energy (BMWi). (av)